Avoid Green Solderable Finishes

A look at solder mask contamination on pads.

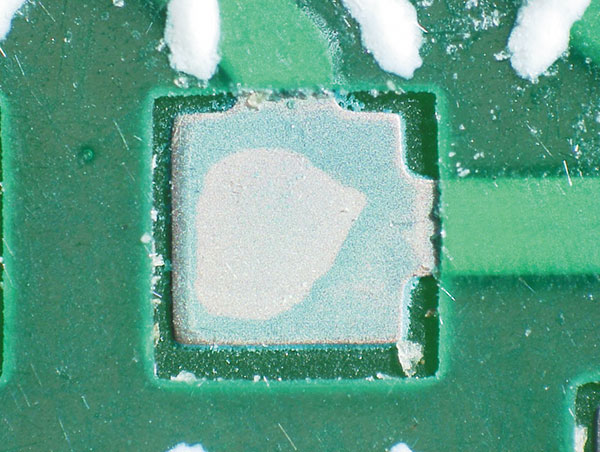

This month we look at solder mask contamination on pads. FIGURE 1 is a very, very bad example that never should have made it to the customer. Solder mask residues are visible on the surface and around the edge of the pad. There is also a level of solder mask undercutting.

FIGURE 1. Solder mask residues.

This would not be acceptable per any standard and would have shown complete nonwetting during soldering. This would have led to a bad day in the office for the assembly engineer or, more important, the shop floor staff.

We have presented live process defect clinics at exhibitions all over the world. Many of our Defect of the Month videos are available online at youtube.com/user/mrbobwillis. Find out how you can share our new series of Defect of the Month videos to explain some of the dos and don’ts with your customers via CIRCUITS ASSEMBLY: https://bit.ly/3mfunlF.

is a process engineering consultant; bob@bobwillis.co.uk. His column appears monthly.