Stencil Tension: The Proof’s in the Printing

Which holds up better: mesh-mounted or mechanically tensioned, mesh-free frames?

Which holds up better: mesh-mounted or mechanically tensioned, mesh-free frames?

Ah, stencil tension. A subject near and dear to my heart and one I’ve written about before in this space. In fact, we covered the subject a few years back, when we discussed how the loss of tension on a conventional mesh-mounted stencil can adversely impact printing results and why other solutions may prove superior. In recent years, studies undertaken to evaluate the impact of stencil tension on print performance have, indeed, confirmed these assumptions.

Before we get into the outcomes of our company’s work, let’s review the basics of conventional mesh-mounted frame stencils and mechanically tensioned, mesh-free frame systems. To be fair, mesh-mounted stencils are the industry standard. They are the predominant stencil type employed for electronics assembly. The alternative approach is mechanically tensioned, single-frame solutions that allow manufacturers to use one frame alongside multiple foils for various assemblies.

Mesh-mounted stencils are a perfectly fine tool, particularly when they are fresh out of the box with tight mesh, strong adhesive bonds and tension at around 35 Newton/cm (N/cm). This is a fairly standard tension for stencils and is necessary for a repeatable and controlled print process. The challenge for mesh-mounted stencils is their propensity to lose tension over time. Wear and tear from thousands of print strokes, in addition to cleaning degradation of adhesive bonds from exposure to chemistry and heat, can quickly cause a mesh-mounted stencil to lose its tension. Once a bit saggy, stencil-related issues begin. During the separation phase after printing, the stencil may peel away from the board at different intervals instead of snapping clean away uniformly across the whole of the PCB. This stencil tends to want to hang around a bit longer in the high-aperture-density areas where there is more solder paste material and releases more quickly from areas where apertures are sparser. This may result in poor gasketing, print deposits with non-brick-like shapes such as peaks or dog ears due do differing deposit volumes, as well as poor alignment issues.

Mechanically tensioned frame systems, which provide foil tensions of approximately 32 N/cm for standard versions and 47 N/cm for high-tension versions, provide a solution whereby tension is maintained over the life of the stencil. There is no mesh or adhesive to degrade. Instead, a stencil foil is placed into the frame and, using air pressure, mechanically tensioned to a specific tension every time. This eliminates many of the problems associated with mesh-mounted stencils. It is well-known that a loss in stencil tension can present printing challenges, and consistent, repeatable tension alleviates many of these issues. Recently, a study conducted in collaboration with our company’s academic partners at Rochester Institute of Technology proved the advantages of mechanically-tensioned – and particularly higher tension – stencils, especially for finer-pitched, higher-density assemblies.

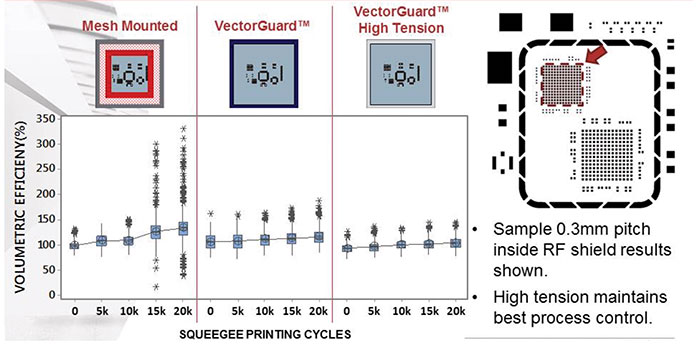

The investigation analyzed the impact of stencil tension when printing a board application representative of that for a mobile phone with challenging dimensions, including 0.3mm-pitch CSP apertures inside an RF shield. The stencil thickness was also challenging at 60µm. Three different stencil types were used: 1) a conventional mesh-mounted stencil with stainless-steel foil; 2) a mechanically tensioned stainless-steel stencil at standard tension; and 3) a mechanically tensioned stainless-steel stencil at high tension. Solder paste inspection data were collected for each stencil at print cycle intervals of new, 5,000, 10,000, 15,000 and 20,000 prints. The results bore out what we believed true about the impact of stencil tension. Initially (after very few print cycles), all new stencils produced similar quality prints. However, as strokes began to accumulate, the stencil foils exhibited different wear characteristics and, ultimately, the high-tension foil in the mechanically tensioned frame system exhibited the most stable print results over the course of the endurance print runs (FIGURE 1). Apertures inside the RF shields were especially sensitive to stencil wear, and the mesh-mounted stencil foil had the worst performance in terms of maintaining print control within this region. It should also be noted that, during testing, none of the stencils or frames was subjected to automatic stencil cleaning systems. Each foil was manually hand-wiped, and the mesh was not exposed to any chemistry, so the response was purely an evaluation of each foil’s tension and the effect of squeegee wear. In the case of stencil cleaning under production protocol, chemistry exposure to the whole frame of the mesh-mounted stencil in an automatic cleaner may further accelerate the poor printing results. Alternatively, in the same setting, the mechanically tensioned frame would not be exposed to cleaning chemistry since the foil is removed and cleaned independently.

Figure 1. Print performance with the mesh-mounted stencil degrades as print cycles increase and tension decreases, while mechanically tensioned stencils show much better results. Note: more than 100% solder paste volume is not necessarily problematic, but over 150% should be of concern.

It’s clear tension consistency from print to print is critical, particularly for miniaturized, high-density assemblies. Even with so-called standard SMT, however, a loss of tension will likely result in subpar print outcomes. Keep it tight, people!

: Many thanks to my colleague, Jeff Schake. His work, and that of Prithvi Kotian at Rochester Institute of Technology, provided the stencil comparison transfer efficiency data for this column.

is global applied process engineering manager at ASM Assembly Systems, Printing Solutions Division (asmpt.com); clive.ashmore@asmpt.com. His column appears bimonthly.

Press Releases

- Tagarno Sees Strong US Sales Growth in 2025, Driven by T50 and Software Demand

- Kimball Electronics Sets Date for Ribbon-Cutting at New Indianapolis Medical Manufacturing Facility

- Nordson’s SELECT Synchro Selective Soldering System Helps Kamstrup Advance Automation, Increase Output 20%, and Reclaim 6 Meters of Factory Floor Space

- Pinnacle Technology Group, Now PTG Electronics, Launches New Brand Identity, Strengthening Its Commitment to Innovation and Progress