Component Obsolescence Management

Ways to avoid redesign due to discontinued parts.

Ways to avoid redesign due to discontinued parts.

Electronics found inside infrastructure items such as buses, trains, signage, control units – anything that requires a printed circuit board assembly – are usually expected to have a long lifespan of continuous operation.

Each of those electronic systems and their corresponding subsystems can be affected by component obsolescence, however, especially when the components placed into them today have a purchase availability of only about 10 years.

This is because changes in design, improved component speed and efficiency, a drop in demand, etc. lead to component replacement and can make older components obsolete.

That’s why component obsolescence management is so important for OEMs.

Yet many governments and other larger customers of OEMs are not thinking about obsolescence. They assume the electronics they purchase will last more than 10 years. But OEMs must plan for the electronic components in their products today to be discontinued within five to 10 years of the original design.

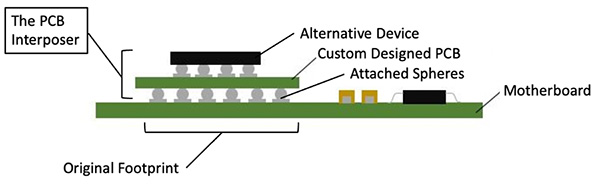

Figure 1. A diagram of a PCB interposer, or daughterboard.

How do they do that? Through careful obsolescence management.

Component obsolescence management is a newer discipline, requiring a strategic approach that identifies which parts of every product may become obsolete. And it involves continual monitoring of the availability of key components.

When an OEM becomes aware that a component manufacturer is going to declare a particular device obsolete, it must either make a lifetime buy or redesign the part.

Many OEMs make a lifetime buy, as redesigning and revalidating a particular product can be very expensive. A good plan involves significant amounts of electronic components in stock to cover its production and service needs. The smarter plan involves managing that inventory cost through long-term maintenance contracts.

A redesign of product might be necessary if a lifetime buy of a component that is about to become obsolete is not available. A costly redesign at the system level may not be needed, however, if the redesign can be performed at the component level with a PCB interposer or adapter.

An interposer provides a flexible, cost-effective, and efficient solution to the challenge of semiconductor obsolescence or unavailability.

When a semiconductor component becomes obsolete or has a lead time beyond 52 weeks, finding a direct replacement that fits the existing system’s footprint can be challenging.

Figure 2. PCB interposers can provide a solution to semiconductor obsolescence or unavailability.

An interposer (also known as a daughterboard) is a small electronic assembly that has a custom-designed PCB with components that mimic the function(s) of the original IC. That PCB contains the I/O interconnect that emulates, or is an upgrade of, the performance of the original IC.

More importantly, it is manufactured with the same footprint as the original IC, can be shipped in tape-and-reel or in a JEDEC tray, and attaches using conventional SMT assembly processes.

The PCB interposer acts as a bridge between the new component and the old system, permitting integration of modern semiconductors into legacy systems without the need for extensive redesign.

By permitting the integration of newer semiconductor technologies into older systems, adapters and interposers ensure these systems continue to function and remain relevant, despite the original components being phased out or not immediately available.

Implementing an adapter is typically faster than undertaking a full system redesign. This speed is crucial for industries where time to market and system uptime are critical factors, as interposers eliminate the need for extensive technical re-evaluation and redesign, simplifying the upgrade process.

Interposers also offer PCB buyers and engineers more options. They are often more economical than redesigning the entire system or product to accommodate new semiconductor components. This approach saves time and money.

Custom-made interposers also prevent costly last-minute or risky gray-market buys.

Obsolescence is a risk – a risk most customers don’t understand or consider as part of their quoting process. OEMs don’t have that luxury. Obsolescence management is key to both product longevity and customer satisfaction.

has more than 25 years’ experience selling PCBs directly for various fabricators and as founder of a leading distributor. He is cofounder of DirectPCB (directpcb.com); greg@directpcb.com.

Press Releases

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging

- ECIA’s February and Q1 Industry Pulse Surveys Show Positive Sales Confidence Dominating Every Sector of the Electronic Components Industry

- Hon Hai Technology Group (Foxconn) Commits To New 5-Year Sustainability Roadmap Through 2030

- Amtech Electrocircuits Navigates Supreme Court Tariff Ruling