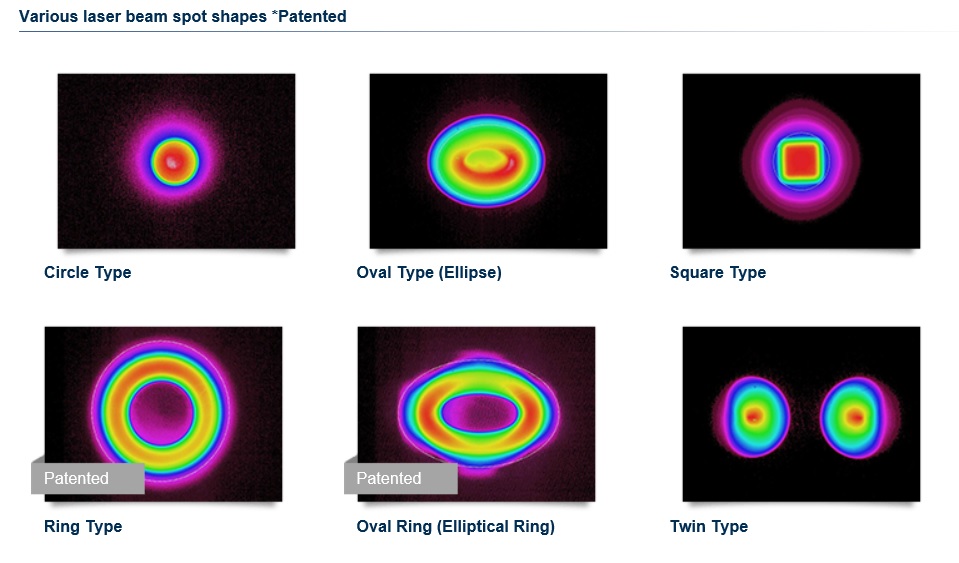

Laser shape rings aid selection of optimal laser spot shape to fit components and land shapes to reduce circuit board problems. Come in twin-spot, circle, square, ring and oval ring. Help avoid inadvertent burning of PCBs. Twin-spot enables simultaneous soldering of two joints.

Japan Unix, japanunix.com/en/products/laser/shapes.php

• Verification video showing how incorrect laser shapes burn components: youtube.com/watch?v=iqjpVepqWbU

• Twin beams working two components simultaneously: youtube.com/watch?v=vRWr80bnCfg

Pressure-Sensitive Cover Tape 2698 transparent, polyester film tape has synthetic, room-temperature, pressure-sensitive adhesive zones at its sides. Helps eliminate pick-and-place errors, minimize down-time and increase productivity. Is said to enable near-flawless placement of chips on circuit boards without sticking, static charge or contamination. Comes in standard widths and 600m reels designed to reduce changeover time and enable productivity improvements. Compatible with existing industry-standard equipment.

3M, http://www.3m.com/transport

THT-Line AOI for double-sided inspection of plated through-hole assemblies now comes with tape transport in addition to roller conveyor for work piece carriers. Inspects selective solder joints on assemblies transported without work piece carrier. Can be used both for actual manufacturing process in the upper area of the system as well as return transport in lower area of the machine. Also has laser measuring system for coplanarity control (e.g., for connectors) or for height measurements on various components. Up to two different and independently operating AOI modules can be integrated into a single system chassis.

Goepel Electronics, www.goepel.com

EMS 618-15 is a room temperature cure two-part conductive adhesive for printed circuit board assembly applications. Is said to cure in 24 hr. at room temperature or rapidly at elevated temperatures. Has a 10-to-1 mix ratio and comes in a two syringe package designed for use with static mix heads. Forms high-strength, high-reliability conductive interconnects.

Engineered Material Systems, www.emsadhesives.com

Unix FS flash soldering series has a speed upgrade with an integrated optical laser configuration; is reportedly two times faster than a typical laser. Can integrate pre- and post-soldering processes such as surface mount and through-hole devices. Depending on conditions, 100 points can be soldered in fewer than 30 sec. at <0.25 sec./point. Integrates soldering process for solder paste and wire; has a coaxial camera that follows soldering work scenes. Soon will feature automatic correction and error detection. Is possible to integrate pre- and post-soldering.

Japan Unix, www.japanunix.com

ACT100Lite automatic wet scrubber for metal masks used in solder printing is said to reduce costs and space requirements by limiting metal masks’ size to small. Uses a novel small-area scrubbing method. Scrubbing and drying occur inside scrubber, eliminating contact with solvent and exposure to airborne cleaning solution for operator safety. The simple configuration minimizes maintenance costs and the need to replace consumables.

OKI Communication Systems, http://www.oki.com

Press Releases

- AIM Solder Hires Francisco Rodriguez as Regional Sales Manager for Northeast Mexico

- The Test Connection, Inc. Adds Creative Electron Prime TruVision™ X-ray and CT System for Deeper Failure Analysis

- Kurtz Ersa Goes Semiconductor: Expanding Competence in Microelectronics & Advanced Packaging

- ECIA’s February and Q1 Industry Pulse Surveys Show Positive Sales Confidence Dominating Every Sector of the Electronic Components Industry