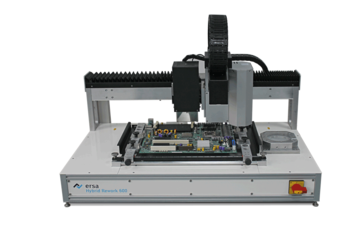

HR 600 hybrid rework system features bottom-side heating (2400W) divided into three independent heating zones. Hybrid topside emitter provides 800W of heating power and combines infrared and convection heating. Uses closed-loop technology. Component temperature is measured and can be controlled exactly. Noncontact temperature measurement performed via digital IR sensor (pyrometer). Optional visual process control and dip-and-print processes for solder paste or flux application. Can be adapted modularly and step by step for future rework requirements. Footprint about 85 x 60cm.

ERSA, www.ersa.com

HS70XL inline SPI handles printed circuit boards up to 22 lbs (10kg). Features sensor head camera, timing conveyor belt, and four sets of motors. Uses dual CPUs to handle data. Measuring speed is 80cm2/sec. at 20x10 micron resolution, and 40cm2/sec. at 13x7 micron resolution. Inspects smaller than 01005 pads and sizes as small as 100u microns.

Parmi, www.parmi.com

NXTP-M25 screen printer has two lanes for increased throughput and changeover. Features one-sided operation and the ability to place machines back-to-back. Mask accuracy reportedly is ±10 um. Features low-impact clamping to reduce warpage when panel is clamped. Optional automatic solder supply method minimizes waste.

Fuji Machine Manufacturing Co., Ltd., fuji.co.jp

Ecoselect 1 selective soldering system requires less than 3m² of space. Is semiautomatic; uses same technology as Versaflow system. Can handle printed circuit boards sizes up to 406 x 508mm. Includes spray monitoring and continuous pressure monitoring of the flux storage tank. Is equipped with a full-area preheater. Bottom-side heating consists of eight emitters that can be switched in groups to match their power with the assembly’s heat requirements and size. Has universal pallet conveyor; fluxer module with precision spray fluxer; bottom-side preheating via short-wave, dynamic IR emitters; top-side convection heating; Pb-free single point solder module; second solder pot to process two different solder alloys; second solder pot to process multi-up panels; camera/screen for solder process monitoring; barcode scanner; CAD data download of board layouts; operation via touch panel; traceability according to ZVEI standards, and fiducial recognition standard/option.

Ersa, www.ersa.de

FIS Track and Remote modules interface with external software systems like MES (Manufacturing Execution Software). Enable automated collection and export of programming results, to support traceability, reduce risk of recalls and minimize scrap. Provide remote control of programming commands, eliminating operator errors related to job selection and downloads, and ensuring that the correct data is programmed into the correct device on each line.

Data I/O, dataio.com

KE-3020V placement machine has a six-nozzle laser head plus a one-nozzle high-precision head with CDS sensor. Places 17,100 cph per IPC-9850; component range is 01005 to 74 x 74 mm or 50 x 150 mm; 25 mm high. Placement accuracy ±50 [U]m @3 Sigma using laser centering. Optional module processes flip-chips directly from wafers.

Juki Automation Systems, www.jas-smt.com

Press Releases

- Altus Reports Growing Demand for Guidance on Convection Reflow Oven Specification

- Coherix Opens New Adhesive-Dispensing Vision Center in Europe

- Pan Pacific Strategic Electronics Symposium Program Finalized

- The Most Critical 2 Inches in SMT Manufacturing – When a Splice Fails, the Line Fails, Full Stop. Throughput and Yield Depend on One Overlooked Moment