Products

TruView XL x-ray inspection system is large sample capable to inspect LED panels, communication backpanels, large printed circuit boards, electronic components, and mechanical parts. Viewable area is 20" x 40"; max. sample size is 20" x 80". X-ray source voltage variable up to 80kV, 90kV, 130kV, or 150kV. Sample manipulation is fully automated in x, y, z and camera tilt. Magnification up to 1000X.

Creative Electron, www.creativeelectron.com

Photon steam aging system meets military and commercial reliability specifications of J-STD-002 and other applicable standards for artificial aging of all electronic components and circuit boards. Designed to accommodate all package styles including high density, discrete components, relays, transistors, capacitors, including SMT and axial components.

Hentec Industries (formerly RPS Automation), rpsautomation.com

Pulsar solderability test system provides precise handling of electronic components for automated flux and solder dipping of component terminations according to requirements of J-STD-002 and other applicable standards for the “Dip and Look” method. Reportedly can tin virtually any component from axial resistors to QFPs and other leaded and leadless packages.

Hentec Industries (formerly RPS Automation), rpsautomation.com

Dymax Multi-Cure 9451 conformal coating is a "true" black material -- a single-component, 100% solids, light and heat curable conformal coating. Is designed to enhance security on PCBs. Improves circuit reliability in harsh conditions. Opaque black color is intended to cover markings, labeling, other identification as well as sensitive information on the PCB. Formulated with a secondary heat cure, can typically be applied and cured at up to 5 mils thick -- in one pass -- for applications where shadow areas exist. Is dispensable; and can be applied in multiple passes for thicker coating requirements. Immediately tack-free after curing. Applies to glass reinforced epoxy laminates, glass and stainless steel. Complies in full with RoHS Directives 2002/95/EC and 2003/11/EC.

Dymax, dymax.com

Sarcon GAR glass fabric-reinforced thermal interface material delivers thermal conductivity of 3W/m°K, while exhibiting a thermal resistance as low as 0.17°Cin2/W. Is for complex die-cut shapes and exerts a low force on components, as it fills air gaps between the heatsink and board-level heat sources. Comes in three thicknesses: 0.2, 0.3, and 0.45mm; is offered in rolls, pre-cut sheets or can be die-cut. V‐0 equivalent thin film is recommended for applications with operational temperatures from ‐40°C to +150°C.

Fujipoly America Corp., www.fujipoly.com

MP2 all-in-one DPSS laser marking system is for applications requiring high resolution but not high-speed throughput. Diode pumped solid state (DPSS) provides pulse duration of 3ns, high peak power of 30kW and runs on 24 VDC (6A). The 1064nm infrared wavelength is suited for marking a range of materials – metals, plastics and some organics. Includes laser beam scanning optics (galvanometer), control electronics and marking software. Optional laser safe enclosure.

LNA Laser Technology, lnalaser.com/dpss-laser-marking-system

Compliance Map Origin Determination Module is said to to simplify origin tracking within a complex manufacturing supply chain. Through a single dashboard, allows monitoring of an entire supply chain for compliance and quickly identification of country of origin. Substantial transformation calculations provide traceability with calculated origins rolled-up through bill of materials data. Is targeted at electronics and medical device manufacturing companies, especially components used in electronics assembly. Automatically collects country of origin data from the supply chain, applying rules of origin such as determining if the product was wholly produced in one country or if Substantial Transformation took place. Criteria such as Regional Value Content analysis can be automated to roll through the BOoM and provide a calculated and accurate origin determination. Integrates with source data, such as PLM/ERP and warehousing systems, for up-to-date, accurate and traceable origin determination. Automatically reviews tariff changes based on BoM and supply chain information and marks products appropriately.

The Compliance Map, thecompliancemap.com

Z:TA-R / YSM40R modular surface mount placement machine has placement rates of 200,000cph. Has a 1m‐wide platform, a 4‐beam layout and multi-nozzle rotary head. High‐speed head is capable of simultaneous pickup and simultaneous vision recognition. Has high‐rigidity base frame, lightweight X-gantry, and high‐speed side-view camera. Is compatible with components down to 0201.

Yamaha Motor Intelligent Machinery, www.yamaha-motor-im.com

Machine vision smart camera is compact and flexible to meet the needs of on-board image acquisition, vision processing and communications options. Is capable of high-performance barcode reading and complex vision inspection, enabling automatic identification, quality assurance and guidance applications. Features integrated liquid lens autofocus technology.

Microscan, www.microscan.com

ST5S-BT Smart Tweezer is a handheld LCR- and ESR-meter with a Bluetooth-enabled connection. Remotely records measurements. Offers basic accuracy of 0.2%. Can connect to computers and NI Labview via USB receiver stick that enables a virtual serial port.  Is based on ST-5S Smart Tweezer model. Data can be received by any communication software.

Is based on ST-5S Smart Tweezer model. Data can be received by any communication software.

Siborg Systems, www.siborg.com

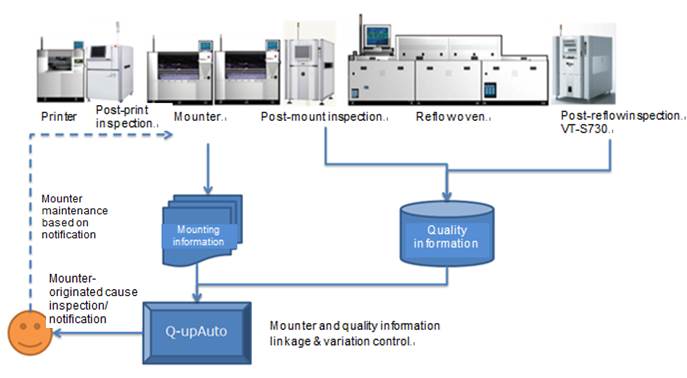

Q-upAuto quality control system links component mounters and inspection equipment and integrates the information they produce. Simplifies quality control of the entire PCB-mounting line, which conventionally has required highly expert knowledge and enormous working hours, thus contributing to defect prevention and enhanced productivity. Upgrades defect analysis platform from Q-upNavi Series; identifies defect causes among multiple factors and extract optimal setting conditions (parameters) for individual facilities, based on final quality inspection. Links quantitative inspection results to information on operation of component mounters to identify defect causes in multiple processes including printing, placement and reflow.

Omron, omron.com

Surface-Cure Thermal Paste is stable during thermal shock testing. Fills gaps that naturally exist between two metal surfaces placed one upon the other, improving the effective range of surface area for heat transfer. Does not set. Remains malleable when rework of components is required. Resists pump-out of the thermal interface layer from the bond line, ensuring minimal degradation of effective heat dissipation.  For applications that are exposed to rapid and frequent changes in temperature. Thermally stable up to 200⁰C. Applicable using conventional industrial dispensing equipment and can also be applied via screen/stencil printing directly onto the contact surfaces. Contains no solvents and can be applied to very thin films.

For applications that are exposed to rapid and frequent changes in temperature. Thermally stable up to 200⁰C. Applicable using conventional industrial dispensing equipment and can also be applied via screen/stencil printing directly onto the contact surfaces. Contains no solvents and can be applied to very thin films.

Electrolube, electrolube.com

Press Releases

- NEPCON ASIA 2025: Innovating Smart Manufacturing Ecosystems and Bridging Global Opportunities

- Viasion Technology Expands Global Reach as a Trusted PCB Manufacturer and EMS Provider in China

- Viasion Technology Expands Global Reach as a Trusted PCB Manufacturer and EMS Provider in China

- Nordson Test & Inspection Expands Partnership with Distributor smartTec Nordic A/S