Products

Femto 2 die bonder, for advanced packaging and bonding, has a placement accuracy of ± 0.5µm @ 3 Sigma.

SA series automation feeders use SSF feeder technology to enable a range of interface and control capabilities, including ASCII communication protocol, lower profile form factor and optional SAFP robotic interface module for drop-in integration. Reportedly enable more integration flexibility and control options, particularly when smaller form factor or higher level of performance is required.

Hover-Davis, www.hoverdavis.com

Uflex modular automation platform facilitates user-level programming by leveraging a cloud-based library of predefined process strategies. Is built on high-performance base with 2G acceleration, 50μm accuracy and 8μm repeatability. Supports boards up to 630 x 500mm, components up to 38 x 127 x 50mm, and processes including pick-and-place, dispensing, screw driving, labeling, and test handling. Can be integrated into Lean assembly lines or configured inline.

Universal Instruments, uic.com

Flexbond hot bar bonding is for flex circuit applications. Incorporates up to 18 bond heads that are selectively active based on RFID designation of placements. Uses pulse heat technology, closed-loop temp control and programmable pressure settings. Combines with Fuzion for full-process integration, including flux transfer, high-accuracy placement and hot bar soldering.

Universal Instruments, uic.com

LAS 300.81-HFM054 ATEX-certified extraction and filtration unit is for extraction and filtration of dry dusts that occur during laser processing such as cutting, engraving or structuring. Is classified as a dust extractor according to filter class H, corresponding to dust technical approval tests and meeting DIN EN 60335-2-69.

Suited for extraction and filtration of dry dust particles with TLV <0.1 mg/m³ (threshold limit value) as well as carcinogenic emissions. Features a combination of cartridge and storage filters. Filter elements’ material ensures efficient separation of various particulate matters. Main filtration module consists of two class M cartridge filters with optional Teflon coating, which are jet stream cleaned at regular intervals. Pneumatic dedusting is said to guarantee an extremely high endurance of main filter. HEPA filter H14 is utilized as a secondary filter, ensuring a separation rate significantly higher than 99.995%. Comes with stepless volume flow control, filter condition indicator and interface for control by means of external systems.

Ult, ult.de

Precisioncoat Tool Changer motor-driven 5-axis system makes it easy to quickly pick up the active valve or tool, then drop it off and pick up another. Comes on Precisioncoat V platform. Capable of selecting and hanging up to five valves and/or tools within a single program profile with no operator intervention. Each valve and/or tool has programmable 0-360° rotation and ±0-45° tilt. Because multiple heads are combined into one system, the work area is full 22.5" x 21" (571 x 533mm) on every valve. Pass-through height measures 5" on top and bottom.

Specialty Coating Systems (SCS), scsequip.com

Jewel Box Ultra Compact micro-focus x-ray system fits on a desk or in a small lab. Jewel Box Oversize is designed for backplane and LED panels; can accommodate a 24" x 24" panel. Positioner can scan 23" x 12". Both offer up to 500x geometric and 2,000x electronic magnification and include 5-axis positioner with 360° rotation and 45° tilt. GTI image processing software packages can be added.

Glenbrook Technologies, www.glenbrooktech.com

S3088 ultra gold 3D AOI reaches image data rates up to 3.6gp per sec. Core is XMplus camera module with more than 120mp. Is for small series production to high-volume-low-mix manufacturing. Has image field size of 50 x 50mm and inspection speeds up to 65cm2/s. Works with integrated structured light projector. Fields of view from up to nine perspectives enable 3D analyses. Touchscreen operation and design for vVision and EasyPro inspection software are additional features. Viscom FastFlow Handling is integrated. Has a width of under 40" and a depth of over 60".

Viscom, www.viscom.com

Liqui-Form 3500 thermal interface material is a one-part thermally conductive liquid-formable gel. Is designed to provide a balance between dispensability, low component stress and reworkability. Delivers conductivity of 3.5 W/m-K. Viscosity is stable and maintained during storage, processing and within the application. Reportedly does not suffer from material migration over time. Has low volumetric expansion and stability in continuous use at temperatures as high as 200°C. Has low ionics.

Henkel Adhesive Technologies, www.henkel-adhesives.com/thermal

ASM Siplace Metal Nozzle Magazines are for 7xx/9xx series machines. Are manufactured with a hardened base plate and a non-moving top plate with complete round holes as nozzle garages. Springs and detents hold nozzles in position. Numbers of nozzle garages are clearly marked. Work as drop-in replacements.

Count On Tools, cotinc.com

Clever Dispense 06 manual dispenser has high-speed valves that enable accurate and reliable dots and lines of less than less than 200µm. Handles a range of viscosities (alcohols to silicones). Recipes are conveniently created, tested and saved at the workplace. All recipes are activated using a graphic display. Various authorization levels protects against undesired program changes.

FineTech/Martin, martin-smt.de/en/dispensing/products/clever-dispense-06.html

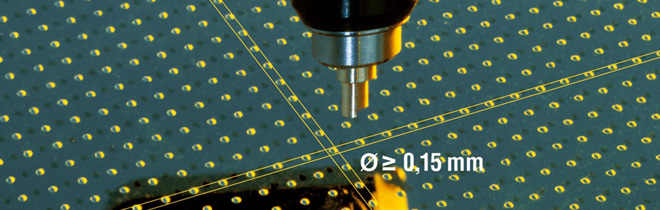

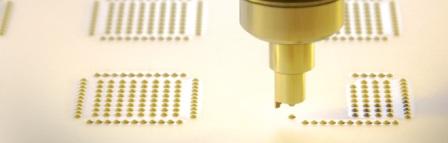

Dotliner 07 automatic, solder paste and SMT adhesive dispenser dispenses 100 micron dots repeatably. Requires no retrofitting, regardless of whether liquid or paste-like materials are used. Features easy dispense wizard software, closed-loop pressure and temperature control in a small footprint and tabletop design.

Finetech/Martin, martin-smt.de/en/dispensing/products/dotliner.html

Finetech/Martin, martin-smt.de/en/dispensing/products/dotliner.html

Press Releases

- The Science of the Perfect Solder Joint

- Q Source Adds Electro-Tech Systems, Inc. to Supplier Lineup, Enhancing ESD and Environmental-Control Offerings

- Dynalec Selects Austin American Technology’s MicroJet EC® to Strengthen Electronics Cleaning Processes

- NOTE strengthens its leadership – Bahare Mackinovski appointed Chief Sales and Marketing Officer